Description

Introducing the Seamless Industrial Pipe from Sanarise Industrial, a testament to our commitment to providing quality, durability, and versatility in industrial piping solutions.

Our Seamless Industrial Pipe comes in a broad range of out diameters, from ¼” to 26”, and wall thicknesses including 20, 30, 40, STD, XH, 80, 100, 120, 140, 160, and XXH. With lengths available from 3.0m to 18m, we are confident that we can supply the exact specifications that your project demands.

One of the key strengths of our Seamless Industrial Pipe lies in its versatility. This pipe is perfect for various applications, including but not limited to:

- Structure Purposes: Ideal for general structure and mechanical applications due to its robust construction and resilience.

- Liquid Services: Its seamless nature makes it perfect for conveying petroleum, gas, and other fluids with reliability and efficiency.

- Low and Medium Pressure: Suitable for steam and boiler manufacturing due to its ability to withstand varying pressure levels.

- Hydraulic Pillar Service: The pipe’s strength and durability make it an excellent choice for hydraulic support structures.

- Auto Semi-shaft Casing: It is also ideal for auto semi-shaft casing, given its high resistance to mechanical stress.

- Line Pipe: Seamless and durable, this pipe is perfect for oil and gas conveying.

- Tubing and Casing: It also finds utility in oil and gas conveying as tubing and casing.

- Drill Pipes: Its robustness and durability make it an excellent choice for well drilling operations.

- Geological Drilling Pipe: The pipe’s seamless construction ensures smooth and efficient geological drilling.

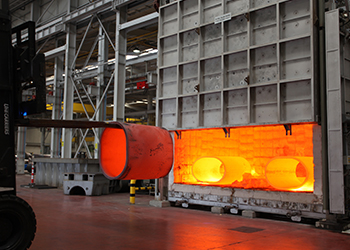

- Petroleum Cracking Tubes: Suitable for furnace tubes and heat exchangers in petroleum cracking processes due to its high heat resistance.

At Sanarise Industrial, we take pride in delivering industrial solutions that meet your needs while adhering to the highest standards of quality and safety. Trust us to provide you with Seamless Industrial Pipes that offer reliable performance, versatility, and durability. Experience the difference of Sanarise Industrial and enhance the efficiency of your industrial operations.

| Standard | Grade | Chemical Components (%) | Mechanical Properties | |||||

|---|---|---|---|---|---|---|---|---|

| – | C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | |

| ASTM A53 | A | ≤0.25 | – | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 |

| B | ≤0.30 | – | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | |

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | |

| ASTM A179 | A179 | 0.06-0.18 | – | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

| ASTM A192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

| API 5L PSL1 | A | 0.22 | – | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 |

| B | 0.28 | – | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 | |

| X42 | 0.28 | – | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 | |

| X46 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 | |

| X52 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 | |

| X56 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 | |

| X60 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 | |

| X65 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 | |

| X70 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 | |

| API 5L PSL2 | B | 0.24 | – | 1.20 | 0.025 | 0.015 | ≥414 | ≥241 |

| X42 | 0.24 | – | 1.30 | 0.025 | 0.015 | ≥414 | ≥290 | |

| X46 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥434 | ≥317 | |

| X52 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥455 | ≥359 | |

| X56 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥490 | ≥386 | |

| X60 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥517 | ≥414 | |

| X65 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥531 | ≥448 | |

| X70 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥565 | ≥483 | |

| X80 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥621 | ≥552 | |