Description

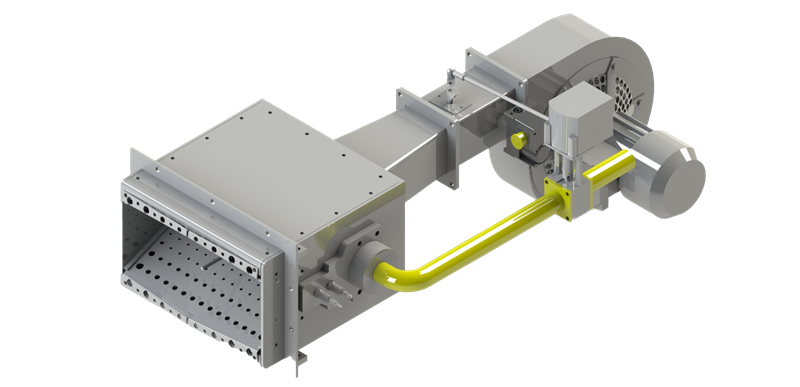

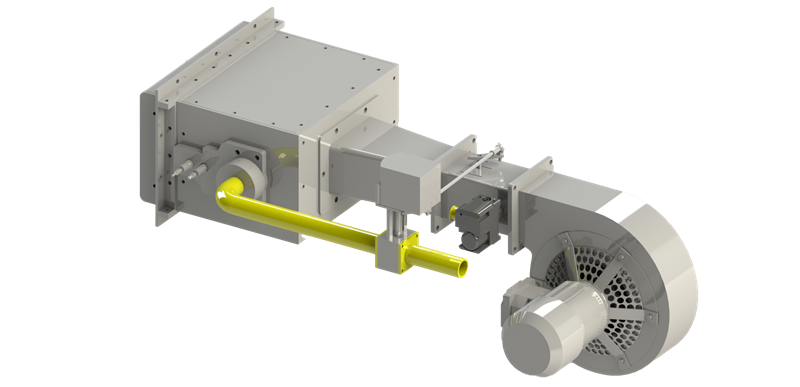

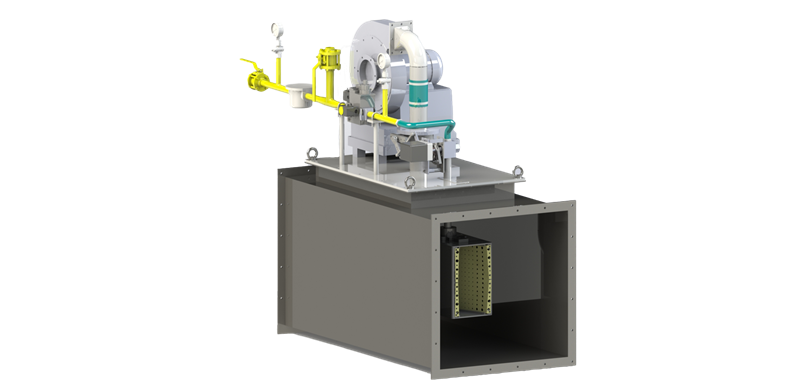

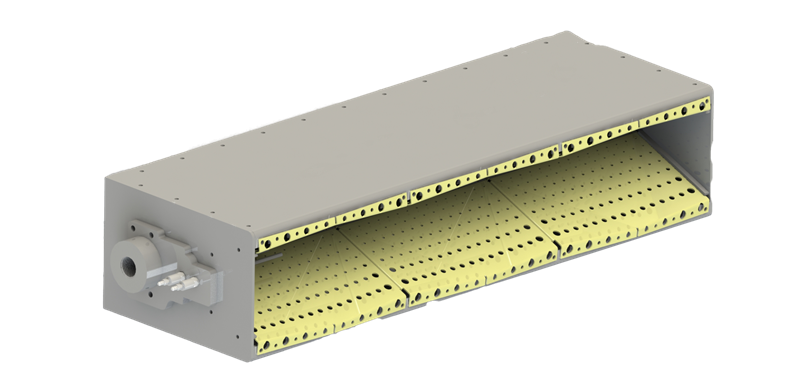

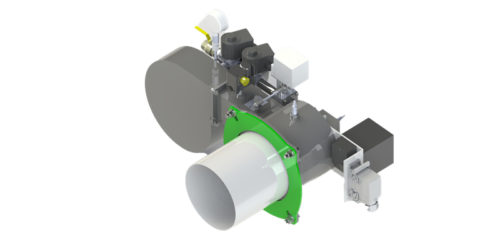

duct burners are used in hot air generation without any need for special combustion chamber. During the process, the burner bodies supply fuel to the center of the air wings and control the air/fuel mixtures. In this way, it optimizes efficiency.

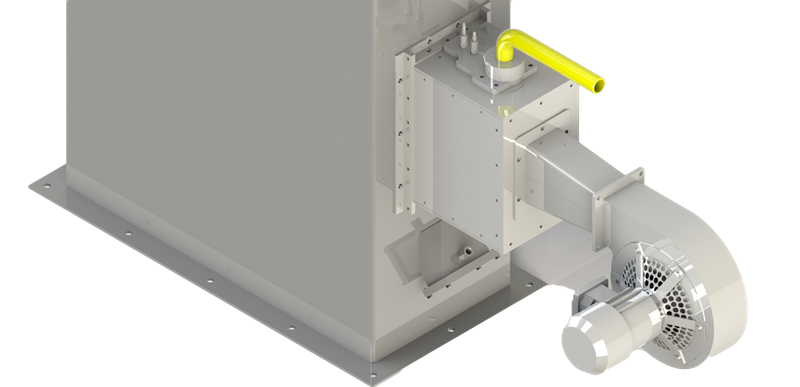

Burner is mounted directly in air ducts. The process air to be heated is mixed with combustion gases to reach the desired temperature.

With reliable modular design, optimum mixing of the flame with the process air is ensured. The greatest feature of those burners, though has the broadest operation range, has to supply simple controlled and high efficiency.

With the duct burners used in air heating, short flame and low flame temperature can be obtained even at high capacities.

SPECIFICATIONS

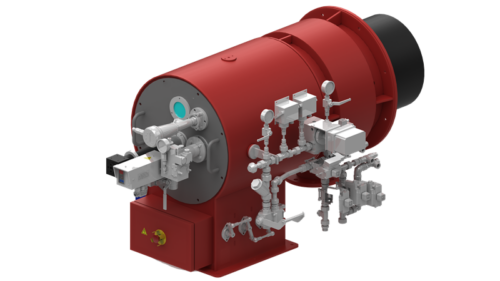

- Operation in wide modulation range

- One stage, two stage and modulating control

- Mechanically and electronically control for modulating devices

- Different design and wide capacity range that allows easy adaptation to many systems

- Easy operation and maintenance

- Easy assembly thanks to its design

- Industry standard and modular line type burner

- Wide variety of configurations available depending on application requirements

- Robust and reliable operation based on extensive history and experience

AREAS OF USE

Textile industry;

- Carpet and similar drying operations

- Paint and press operations

Wood Industry;

- Plywood, MDF and coating drying

Food Industry;

- Drying of products such as corn, wheat, semolina, etc.

Metal Industry;

- Paint drying

Ceramics and Glass Industry;

- Cooling and decoration processes

Other;

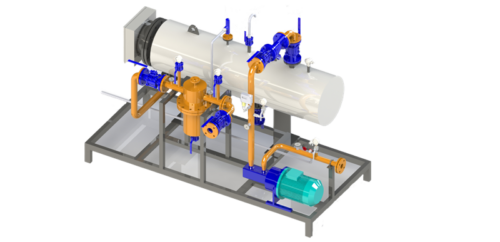

In processes involving furnaces, dryers, smoke incinerators and similar industrial equipment, intended to produce clean and hot air in large volumes

Drywall drying processes

Preheating processes

Paper drying processes

Distillation process

Clay grinding processes

| Capacity | Capacity | Natural Gas Consumption | LPG Consumption | FAN | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Min. kcal/h | Max. kcal/h | Min. kW | Max. kW | Min. Nm3/h | Max. Nm3/h | Min. Nm3/h | Max. Nm3/h | Kapasite Nm3/h |

||

| T/HI 300 | 60.000 | 300.000 | 69,8 | 348,8 | 7,3 | 36,4 | 2,7 | 13,3 | 500 | |