Skip to content

Description

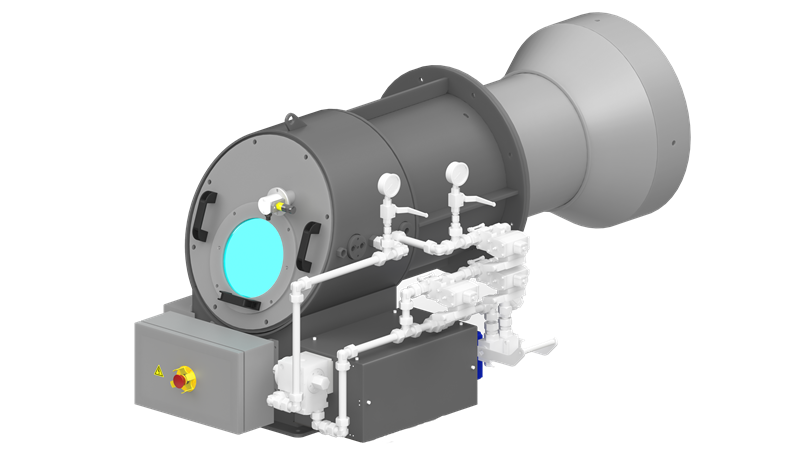

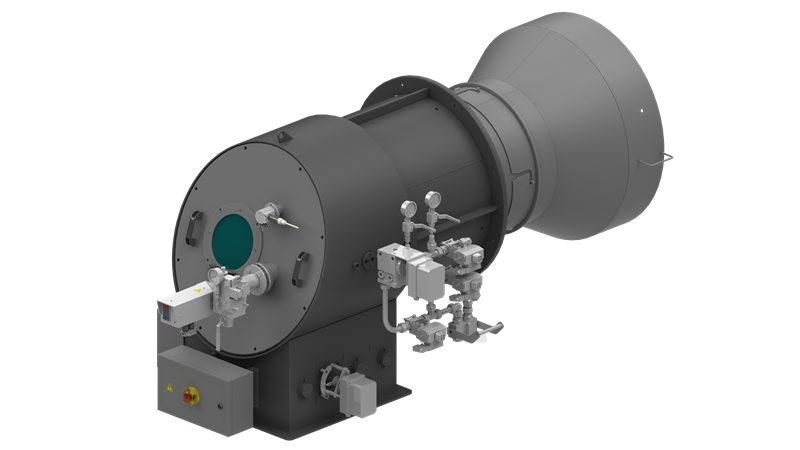

- ECOSTAR ECO series industrial burners with duoblock body structure are used in hot water boilers, steam boilers, hot oil boilers, dryers, fluidized bed and grate boilers and hot air generators in start-up applications.

- It can be used with Natural Gas, LPG, Heavy Oil, Light Oil, Biogas and special fuels in ECO series industrial burners.

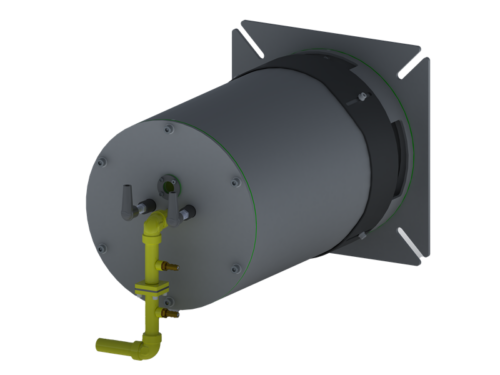

- Thanks to its duoblock structure, the burner body, air control cage and fan can be located in different spaces, offering effective use of this area and flexible process design.

- With different combustion nozzle designs and flame pipe lengths suitable for the process, it can work in harmony in different combustion chambers, including modernized applications.

- Thanks to its high pressure and low pressure liquid fuel lances, it offers various application according to special needs. High pressure mechanical atomization and low pressure air/steam atomization lance options are suitable for use in liquid fuel products.

- According to the process needs, it is possible to control the octopus head and liquid fuel lance with a movable structure in order to move it away from the hot area.

- Able to operate at combustion air fan suitable for the process and at 200°C combustion air temperatures. (It is painted with high temperature resistant paint; product capacity varies in hot air operation.) In hot weather applications, insulation is possible to protect the equipment on the body.

- It has an oblique rear structure due to the optimized air flow with its renewed body structure.

- Thanks to the specially designed protective concrete cover application, a protective barrier can be applied between the combustion chamber and the burner. In this way, it provides long-lasting use by providing burner protection in start-up processes.

- High burning safety thanks to photocell flame control.

- Suitable for manufacturing from completely stainless material in processes that require chemical resistance.

- Possible to request as mechanical and electronic modulating depending on the process needs.

- Depending on the process needs, the control panel can be produced as integrated on the product or as an external panel. In this way, it is possible to use on the process management room or local area.

- Light oil filtering and pumping station is produced externally according to customer demand.

- Light oil filtering, heating and pumping station are produced externally according to customer demand.

- Special design pilot ignition burners for ignition (ECOSTAR PAL burner is standard in ECO-500 series and above) is available,

- Combustion optimization with O2-CO trim system adaptation in electronic proportional burners, if demanded.

- Energy saving with fan speed control in electronic proportional burners, if demanded.

- Remote management by connecting to PLC systems using BMS (Burner Management System) or software.

| Burner Type |

Burner Capacity |

Natural Gas Consumption |

Diesel Consumption |

Fuel Oil Consumption |

|

Max. MW |

Max. kcal/h |

Max. Nm³/h |

Max. kg/h |

Max. kg/h |

| ECO-250.1 |

1,9 |

1.600.000 |

194 |

157 |

166 |

|

ØD |

L |

E |

H |

F |

C |

K |

S1 |

S2 |

S3 |

ØM1 |

ØM2 |

ØM3 |

VL |

DN |

| ECO 250 OS 1 |

Ø219 |

1600 |

650 |

875 |

500 |

1100 |

725 |

250 |

300 |

340 |

Ø330 |

Ø380 |

Ø450 |

320 |

|

| ECO 250 KS 1 |

Ø219 |

1600 |

650 |

875 |

500 |

1100 |

725 |

250 |

300 |

340 |

Ø330 |

Ø380 |

Ø450 |

320 |

DN50 |

| ECO 250 G 1 |

Ø264 |

1600 |

650 |

875 |

500 |

700 |

325 |

250 |

300 |

340 |

Ø330 |

Ø380 |

Ø450 |

320 |

DN50 |

| ECO 250 G 1 |

Ø296 |

1850 |

650 |

875 |

500 |

700 |

325 |

250 |

300 |

340 |

Ø330 |

Ø380 |

Ø450 |

570 |

DN50 |

| ECO 250 OL 1 |

Ø219 |

1600 |

650 |

875 |

500 |

1100 |

725 |

250 |

300 |

340 |

Ø330 |

Ø380 |

Ø450 |

320 |

|

| ECO 250 KL 1 |

Ø219 |

1600 |

650 |

875 |

500 |

1100 |

725 |

250 |

300 |

340 |

Ø330 |

Ø380 |

Ø450 |

320 |

DN50 |

Page load link