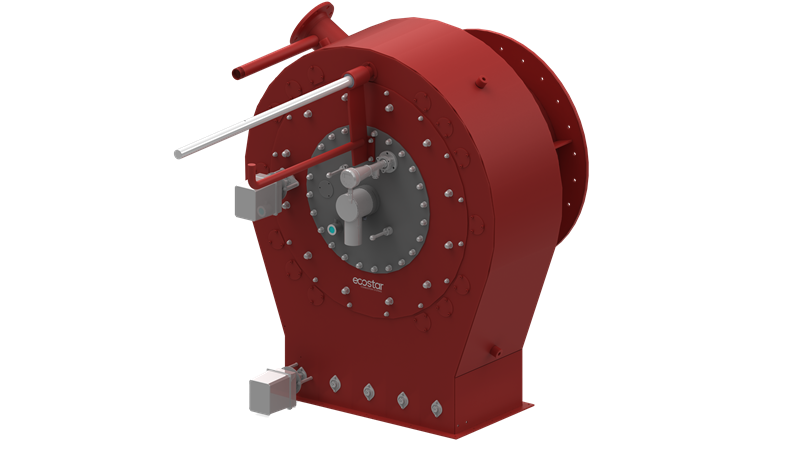

Description

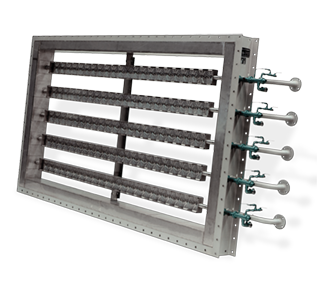

- DSE series industrial burners with duoblock body structure are used in hot water boilers, steam boilers, hot oil boiler applications.

- Natural gas, LPG, Heavy Oil, Light Oil, Biogas and special fuels can be used.

- They have low flue gas emission values with their special body and combustion nozzle designs.

- It can operate in harmony with different flame tube lengths in different combustion chambers and modernized applications.

- According to the process needs, it is possible to control the liquid fuel lance with a movable structure in order to remove it from the hot area.

- Able to operate at combustion air fan suitable for the process and at 200°C combustion air temperatures. (It is painted with high temperature resistant paint; product capacity varies in hot air operation.)

- There is a secondary air control servo in the combustion chamber to intervene in flame diameter and length in line with the process needs.

- A specially designed pilot ignition burner (ECOSTAR PAL Burner is used as standard in DSE series products) is available for ignition.

- Energy saving with optional fan speed control,

- High fire safety thanks to flame control with photocell.

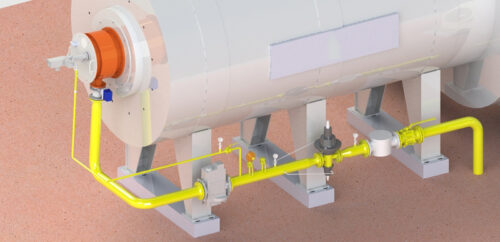

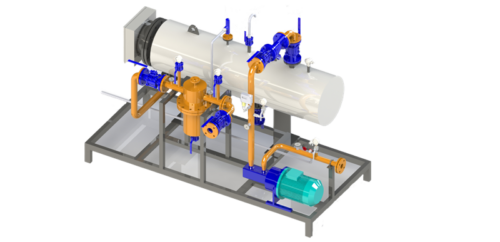

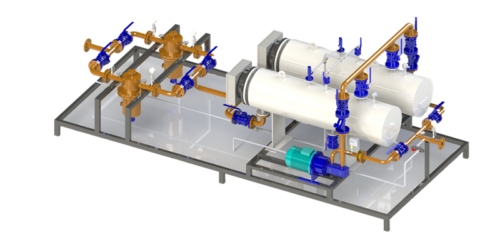

- Light oil filtering and pumping station is produced externally according to customer demand.

- Light oil filtering, heating and pumping station are produced externally according to customer demand.

- Remote management by connecting to PLC systems using BMS (Burner Management System) or software.

- Provides easy installation and maintenance thanks to its service carrying shaft.

*If Low NOx is required for DSE series products, it must be specified at the order stage. The product extension must be selected as LE. (LE extension for LowNOx, SE extension for standard type )

| Burner Type | Burner Capacity | Natural Gas Consumption | Diesel Consumption | Fuel Oil Consumption | |

|---|---|---|---|---|---|

| Max. MW | Max. kcal/h | Max. Nm³/h | Max. kg/h | Max. kg/h | |

| DSE-35 | 9 | 7.740.000 | 938 | 759 | 802 |

| D | B | H | C | L1 | L2 | S1 | S2 | M1 | M2 | M3 | M4 | M5 | M6 | DN | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DSE-35 EL | Ø430 | 1051 | 1325 | 800 | 575 | 860 | Ø790 | Ø650 | 335 | 610 | 375 | 650 | 415 | 690 | |

| DSE-35 MS | Ø430 | 1051 | 1325 | 800 | 575 | 860 | Ø790 | Ø650 | 335 | 610 | 375 | 650 | 415 | 690 | |

| DSE-35 N | Ø430 | 1051 | 1325 | 800 | 575 | 860 | Ø790 | Ø650 | 335 | 610 | 375 | 650 | 415 | 690 | DN80 |

| DSE-35 NEL | Ø430 | 1051 | 1325 | 800 | 575 | 860 | Ø790 | Ø650 | 335 | 610 | 375 | 650 | 415 | 690 | DN80 |

| DSE-35 NMS | Ø430 | 1051 | 1325 | 800 | 575 | 860 | Ø790 | Ø650 | 335 | 610 | 375 | 650 | 415 | 690 | DN80 |