Description

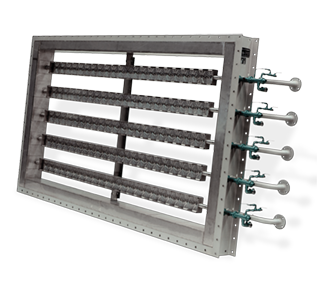

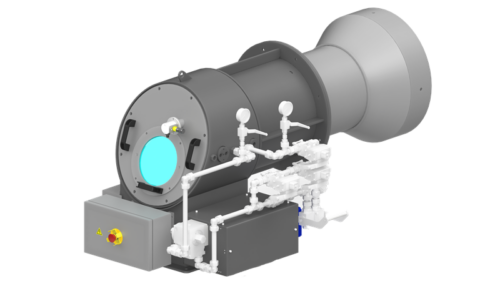

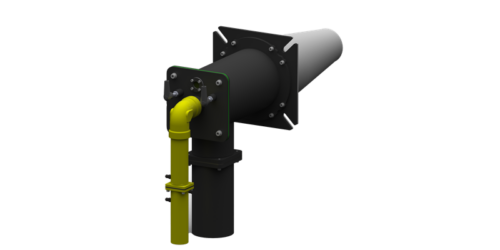

EcoFlue burner has become an industry standard for complementary ignition in co-generation and combined cycle installations. EcoFlue is an in-duct burner that can be directly placed into exhaust ducts between turbine and waste heat boiler. Burner is also suitable for fresh air operation or combustion applications. EcoFlue optimizes the system efficiency by meeting its oxygen need from the exhaust gases.

Burners may be installed directly to the exhaust ducts with high temperatures as well as to the duct inlet for the purpose of use of fresh air. They can also be used by providing an additional inlet to the duct with a spare opening or to the inside of the duct in order to increase the turbine exhaust gas temperature.

CHARACTERISTICS AND BENEFITS:

- Flame stability and emission values

- Clean combustion

- Flame vortex, balancing of combustion right in front of the burner

- Create a mixture of turbine exhaust gases close to fuel.

AREAS OF USE:

- Fresh Air Heating

- In Co-generation Plants:

- Heat Recovery Steam Generator Auxiliary Burner

- Dried Distillers Grains (DDG) Output

- Auxiliary Burner to Joint Steam Generator After Gas Motors

- Combined Cycle Processes Auxiliary Burner