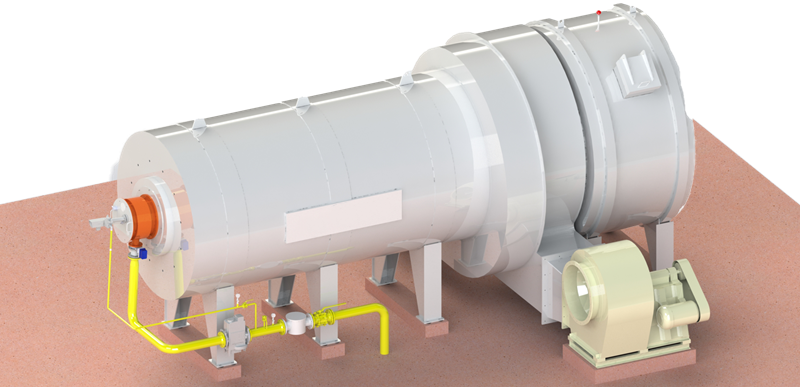

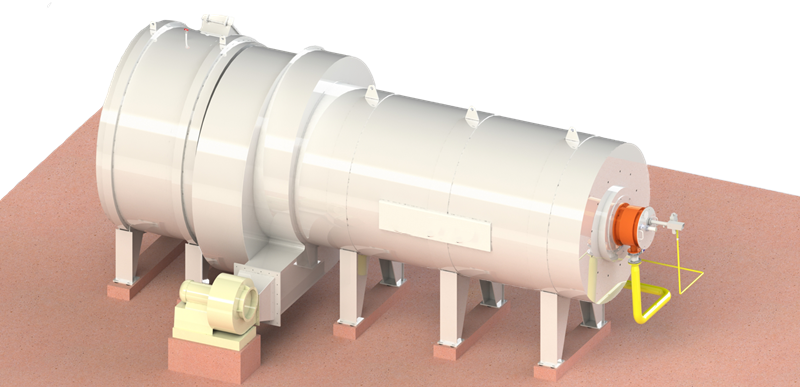

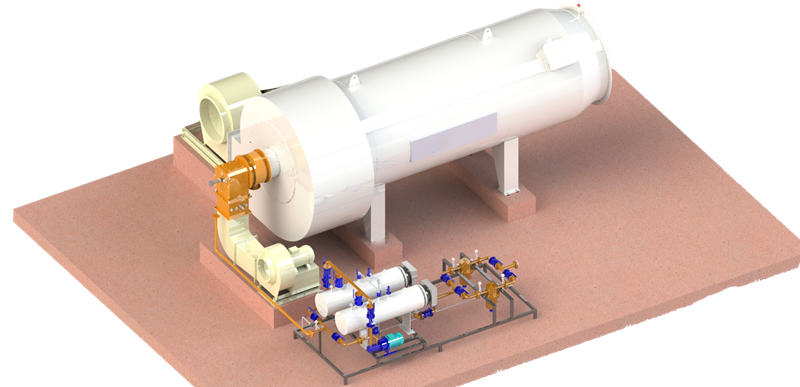

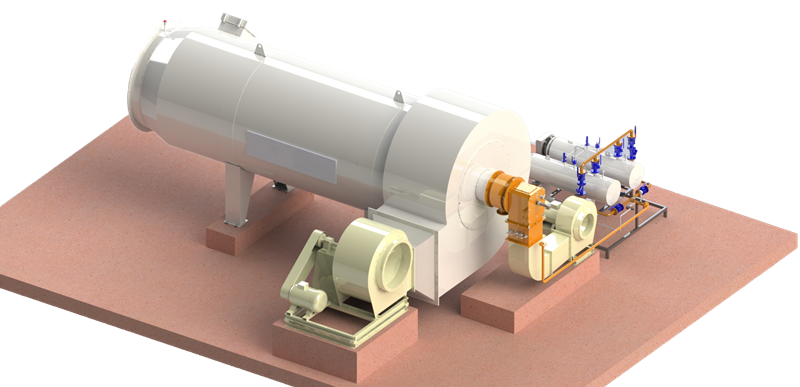

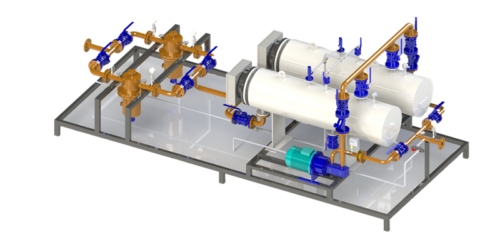

Description

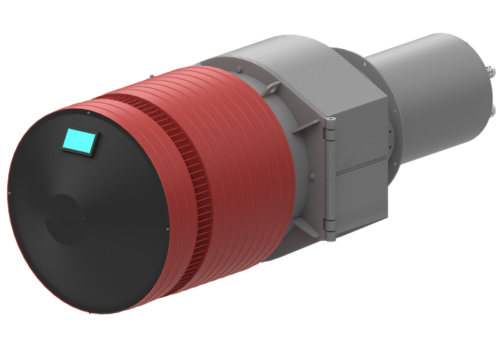

- Durable, solid construction,

- Thermal capacity option of 290 kW- 8750 kW,

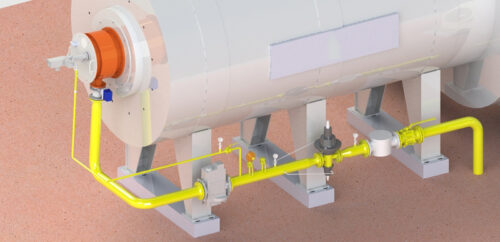

- Operates with gas, heavy oil, light oil and dual fuel burners

- Direct, indirect and brick type design according to process needs,

- Output temperature from 110 °C to 450 °C in direct and indirect hot air generators,

- Output temperature from 450 °C to 800 °C in bricked hot air generators,

- Designs suitable for the process according to different heat capacity values and outlet temperature,

- In direct type hot air generators, minimum heat transfer losses and maximum thermal efficiency increase by direct mixing of burnt gases with air in the mixing chamber, without any heat transmission medium,

- Brick or brick-free combustion chamber design depending on the process, thermal capacity and outlet temperature,

- In brick hot air generators, the refractory brick covered in the combustion chamber and the heating of the air passing around the combustion chamber are resistant to high temperature and temperature stresses,

- Design resistant to high temperature and temperature stresses in brick-free hot air generators, achieved with a combustion chamber manufactured from Chromium-Nickel material, and by heating the mixture air passing around the combustion chamber,

- Special design pilot ignition burner for ignition,

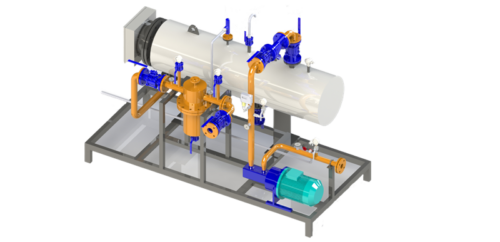

- Reduced operating costs by providing low pressure losses of combustion and mixing air,

- Total increase in efficiency with low flue loss,

- Minimization of heat losses between the body coated with insulation material and the environment,

- Allows exhausting from the explosion cap on the mixture chamber in case of gas entrapment, and also provides easy access into the generator by service personnel for maintenance-inspection,

- Remote management by connecting to PLC systems using BMS (Burner Management System) or software,

- High operating safety,

- Easy installation & operation and low maintenance,

Areas of Use

- Soil Industry: Artificial drying chambers of brick plants,

Sand drying rotary furnaces, gypsum block-gypsum panel drying furnaces,

- Chemical Industry: Detergent manufacturing towers,

- Fertilizer Industry: Rotary fertilizer drying kilns,

- Sugar Industry: Pulp drying kilns,

- Paper Industry: Paper drying,

- Packaging Industry: Print paste drying,

- Metal Industry: Stress relief furnaces,

- Cement Industry: Raw meal drying, coal and slag drying.

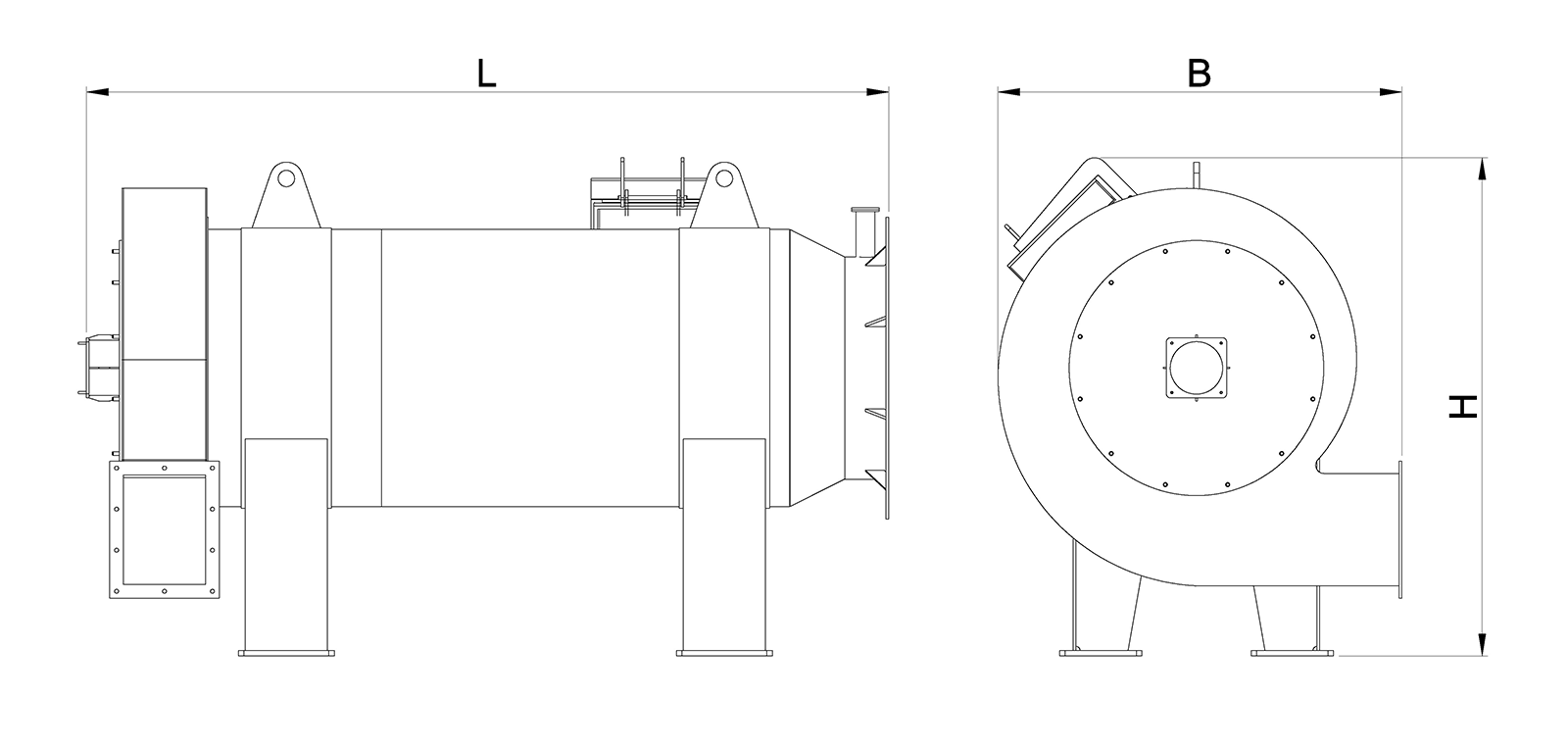

| TYPE | DIMENSIONS (mm) |

||

|---|---|---|---|

| L | B | H | |

| SHG 25 | 2.5 | 1.45 | 2.25 |

| Type | Capacity |

|---|---|

| kcal/h | |

| SHG 25 | 250.000 |